Space Shuttle Launch Complex 39-B Construction Photos

Page 30

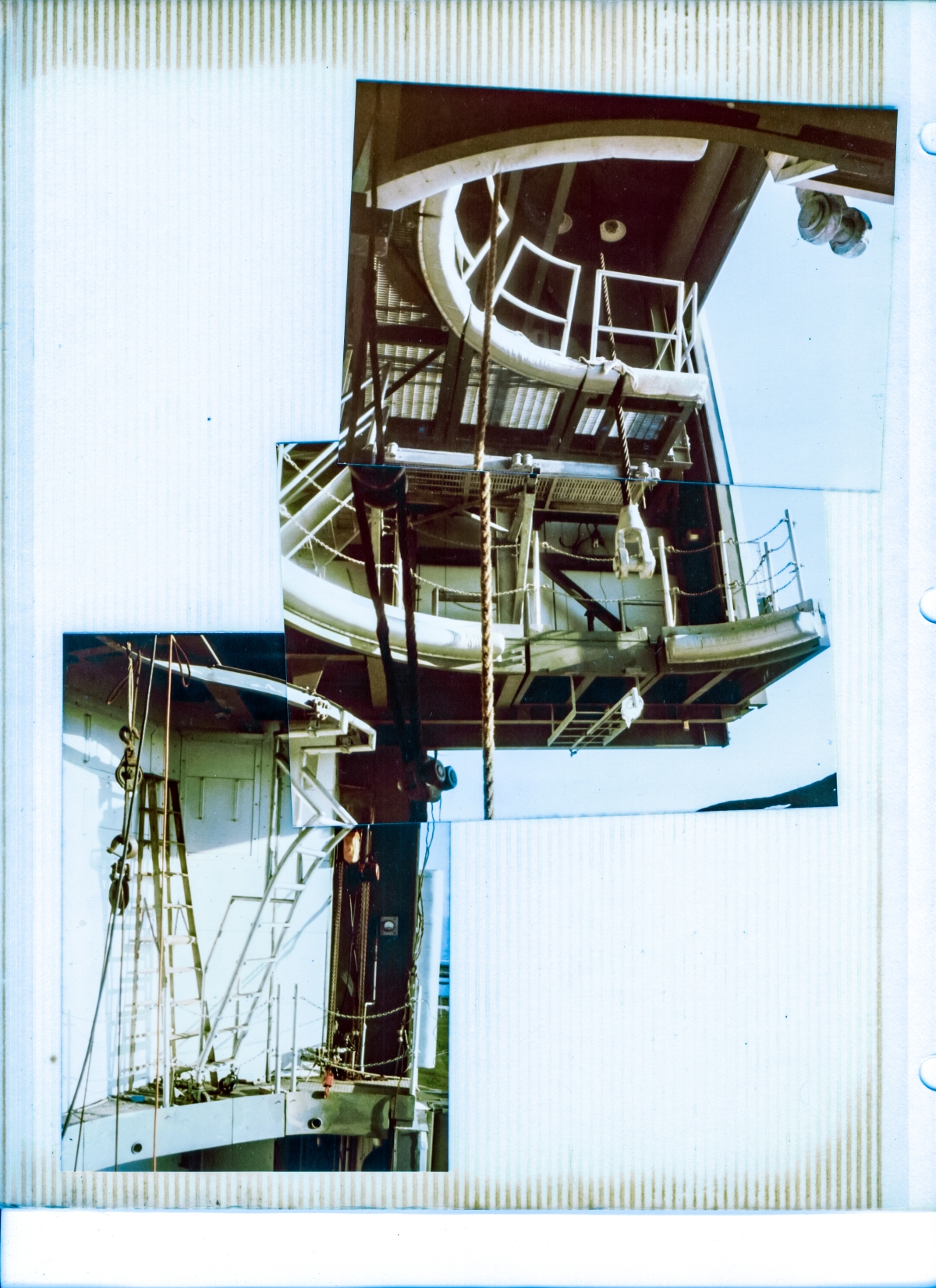

RCS Room in the Crew Cabin Area, Looking out and up, From Below

(Original Scan)

RCS Room, interior looking out, from below. The nose of the orbiter fits snugly into these platform cutouts, and when mated, when you're on the platform just beneath the RCS Room which supports the bottom end of the Rolling Ladder, there's really not a whole lot of room to maneuver around up in there, and you've really got to be careful to avoid contacting TPS tiles. The two very sturdy-looking shackles are what suspends the Payload Canister when it's suspended up in the mated position with the PCR and they're extracting (or, once in a while) inserting payload hardware from it or into it. The funny-looking ladder rolls around suspended on top by a curved monorail (which was lots of fun to fabricate and install, owing to the weirdness of the curve and the tightness of the tolerances for that curve), and is what's used to access the orbiter's cockpit windows.

Additional commentary below the image.

We're just beneath the RCS Room, over on the column line 7 side of the RSS, looking across, out, and up, toward the hinge column side of things.

I have previously mentioned the lower platform (more of a ledge, really, and not a very wide ledge at that, especially where it necks down to a most unpleasantly narrow width in the middle, where the cutout for the orbiter mold line bites frighteningly deep into it) and ladder shown here, on Page 25 of this series, but perhaps I'll go into some more detail with things here, since we can see things quite a bit better than we could in the image on Page 25.

Let's start with the curved gray flat vertical steel plate that comes out of the bottom left corner of this panorama image, and extends upward a little bit above the bottom edge of the frame, as it curves along almost, but not quite, to the far right edge of its part of this composite image.

This is quarter-inch steel plate, and it's what was used in almost all cases, all over the towers, as toe plate.

But clearly, this plate is much taller than the standard 4 inches that was universally used out on the Cape.

And the reason for that is that this particular run of quarter-inch plate was doing triple duty as, 1.) Toe plate, 2.) Perimeter plate for the platform framing upon which it is welded, and 3.) Backing plate for the orbiter inflatable seals that were eventually mounted on it and can be seen

in the top left photograph in the image referenced above.

Look a bit closer, down toward the lower margin of this run of steel plate, and you can see two dark holes, with a vertical seam a little to the left of the right-hand hole.

The holes were for air supply to inflate the seals, and there's two of them because the vertical seam between them denotes that the right hand hole is cut into the steel plate that fronts a separate, flip-up, platform. The rest of the main part of the platform/ledge is fixed in place and remains immovable even as the part on the right gets winched up, out of the way, before the RSS closes in on the orbiter when it's swinging around into the mate position.

This flip-up also had to be lifted out of the way to permit the Orbiter Side Seal Panel (which you can see the very last little bit of the top of, and which runs sixty some-odd feet on farther down out of this frame, along the full vertical extent of the PCR) on this side of the RSS, to be retracted out of the way (it's hinged, and it swings left as seen in this view, toward the interior of the PCR) to permit the RSS to be mated with the Shuttle without smashing into it, taking out the left payload bay door and part of the left side of the fuselage as it does so. Fairly important requirement that this stuff does what it's supposed to, or otherwise we're gonna have a Bad Day at the Launch Pad.

Everything's connected to everything, and everything gets in the way of everything, and everything has to be on hinges or rollers or wire ropes or hooks, or sitting in sockets, or some damn thing to allow it to be moved out of the way, and it all has to be rigidly orchestrated and sequenced for any of it to work.

Once the RSS is safely locked down with the orbiter untouched, they will rotate the side seal panel into position and then lower that platform back down, and then inflate the seals which are there to keep birds and bugs and bats and who knows what else out of the PCR. And even then, once in a while, the birds, or the bugs, or the bats, or perhaps an occasional human will wind up on the wrong side of the seals, anyway. It's tough. It's really tough to keep everything fully-organized, and there's no such thing as a Perfect System.

Zoom in on this image to see the chain hoist that lifts this flip-up and you can also see the hoist hook attached to the lifting eye for the platform through a hole in the toe plate. People think that everything that's going on out at the Cape is done by well-scrubbed scientists wearing spotless white lab coats in an environment of shiny stainless steel and polished glass, but in truth most of it bears a much closer resemblance to what's happening day-to-day in train yards, or on the decks of tug boats, or even drilling rigs out in the oil patch.

So ok. So what? So let's get back to our story. Let's get back to our steel ledge.

So what this means is that the ledge is a little bit wider than it appears in this image, because a bit of it is blocked from view by that upstanding four inches of toe plate you're seeing there.

But the damn thing is still unpleasantly narrow, and the smooth unyielding surface of the vertical steel plate (which, at the narrowest part of things is actually the exterior surface of the by-then-welded-shut Monorail Transfer Doors) on the side of things away from the open edge of the platform checkerplate with its lethal drop right there, right next to you, is constantly pushing you, even when you're not actually touching it, and once the initial novelty of being in a place like this wore off, I never liked going out on this platform, although I did so more times than I'll ever be able to recall or count.

Open steel beams and girders are vastly preferable to a place like this. On an open beam, even when you're way the hell up there, you have a sense of being centered, a sense of security, that the steel wall which crowds you from the side in a place like this never permits you to gain. Also, that laughable set of "safety" chains only served to worsen things, owing to the fact that beyond an ever-present danger of entanglement on the cursed things, followed near-instantly by an awkward flip and fall to your death, they served no purpose at all that I could ever discern. The aluminum handrail posts wobbled in their sockets, and the chains moved obligingly out of the way when you pushed against them, and..... nope. Fuck that noise.

In addition, despite my very-curious and somewhat-adventurous nature which draws me inexorably toward experiences with the novel, the phenomenal, the rare, and the unusual, I sure as hell never trusted my life to that goddamned weird-looking aluminum ladder there,

hanging beneath its very questionable little

wheeled trolley (although that thing was probably rated at two tons and had a safety factor of four, on top of that) that ran along the lower flange of the curved monorail beam.

Never got on it, even once. Never so much as set foot on the lowest rung. Nope. Not gonna happen. From the lower flange of that monorail beam, which is all that's keeping this ladder from going over the side, and down, it's a direct and unimpeded straight shot all the way to the hard flat concrete of the pad deck, waiting patiently over a hundred vertical feet below you.

Nope. Not gonna happen. And like I said, I was a somewhat-adventurous type, and went a lot of places that other folks would never dream of going, but this fucking ladder remained off-limits for the full duration of my tenure on the pad, and that's just the way I liked it.

And, now that I look at this image yet again, I'm none too sure about the confidence I expressed previously regarding how safe and cozy things would get, once the RSS was rotated around to the mate position and the orbiter was filling up all that space next to, and beneath, that rolling ladder. Those inflatable seals were soft (I was involved in proof-testing them with a manometer following installation, and although I do not remember the exact air pressure that was sent into the seals to keep them inflated, it wasn't all too very much. Just a few inches of water in the manometer. Less than one PSI. Quite a bit less, actually. The fabric (I do not recall what it was, and it may have been nylon, or it may have been something a bit more exotic with good flame-retardant qualities.) they were made from was thin, and when you touched or poked them while they were inflated, you immediately noticed that they were quite soft and it looks to me as if there might be just enough room in there between the toe plate and the orbiter to..... Feh. Enough already. Nothing to be gained by dwelling on such things.

Look close, over on the far left side of things up top, and you can see, slightly out of focus, just to the left of a heavy brown rope in the nearest foreground (in the top two of the three overlapping photographs that make up this panorama) where the ironworkers have hung a fairly substantial wire-rope with a shackle at its bottom which is carrying another wire-rope beneath that, going farther down, but in the bottom photograph, this bit of rigging is gone, and I have no recollection at all as to what was going on when I was taking these shots.

To the right, at the extreme top right corner of the panorama, and then again, more toward the middle of things, you can see the swaged boom pendants which hung from the underside of the RCS Room roof, that the Payload Canister was supported from, after it had been lifted into its final working position, and mated to the PCR, using the 90-ton Payload Canister Hoist, that lived in its own separate place, the Hoist Equipment Room, up on top of the RSS, behind the RCS Room.

I forget the actual load rating of these things, but it was substantial with its included safety factors, and of course they were proof-tested after fabrication at Indusco in Jacksonville, (and how 'bout that, I just Googled them, and it looks like they're still around, so I guess I'll take this opportunity to say "Hi" to John Ferlisi, the Indusco guy, who I worked with on this as well as other things and maybe at some point I'll get to tell the little story about me, and John, and the stainless-steel detent pins, and Sag Rod the ironworker's union steward, but not now, ok?) and of course I had to handle all the material certs, and test results paperwork, and god knows what all else, but it was plenty, and NASA was quite excitable about these damned boom pendants, but who can blame them, because if they'd ever dropped that fucking payload canister things would have gotten quite ugly, quite rapidly, and...... gah. I don't want to think about this, either. Must be my day for things I don't want to dwell on or think about, I guess.

They'd lift the canister with the 90-ton hoist when the RSS was rotated around to the demate position, get it into place, hook those ever-so-sturdy boom pedants on up at the top, tie the canister to the face of the PCR using turnbuckles placed here and there along its perimeter, double-check everything to make sure it was all rock-solidly in place, and then unhook the canister from the hoist, and it could hang there on the boom pendants for as long as they needed it to, while they went about their business of opening up the PCR doors, opening up the canister doors, attaching the payload(s) to the PGHM, which would then be rolled back toward the rear of the PCR, out of the way, at which point the canister doors would be closed, PCR doors would be closed, the hoist would be hooked back on to the canister which would then be lifted up just enough to take the tension off of the boom pendants, which would then be disconnected along with everything else, and then the canister would be lowered gently back down to the ground, where its zillion-wheeled transporter was waiting to take it back to the O&C Building, or wherever else they might be wanting to drive it to.

Once all the work with the canister was done, and it was time to roll the RSS around to mate with the orbiter, these pendants would be lifted up and pulled off to the side, behind the folding platforms and out of the way, and tied back securely, to keep them from interfering with the orbiter itself.

Fairly contrapted set of operations, but it all worked well enough. It was a slow process, though.

Around the curved perimeters of two of the upper platform levels that you can see in this image, are the soft "bumpers" which kept hard steel from coming in contact with fragile TPS Tiles in the area around the nose of the Space Shuttle, forward of the cockpit windows.

These bumpers were nothing fancy, and were fabricated by an upholstery shop in Titusville, and I was the guy who drove over there and picked 'em up and then brought 'em back out to the pad, nearly filling up all of the room inside my ratty little yellow VW Beetle and making for less than fully-safe driving by blocking most of my vision in most directions except forward, through the windshield at whatever was in front of me as I was driving. Something about the juxtaposition of ironworkers and upholstery just doesn't seem to fit, but there it is, and that's how it was done. Those bumpers were made by sewing water-repellant cover material over a soft foam interior, with a bit of extra material extending out an inch or two along the back side of things that could be laid flat against the perimeter plate of the platforms they were on, so as a thin metal strip could then be placed on top of that strip of fabric and screwed down onto the metal of the perimeter plate, thus holding the bumper very firmly in place.

Also of some interest is how the hanging cable of the boom pendant passes behind the removable aluminum handrail of the uppermost platform it encounters, and then goes on to interfere with the leading edge of that forwardmost (looking forward, away from the interior of the RCS Room) flip-up platform, necessitating a narrow notch be cut into the perimeter steel of that platform, and a splitting of the bumper that fronts it into two pieces.

In order for that boom pendant to go anywhere, the removable handrail had to be taken out first, or otherwise it would hang up on the pendant, and prevent them from moving it.

Zillions and zillions of eency-teency little goddamned details, any one of which might be fully-capable of stopping the whole damned program until a resolution was found and implemented.

It's truly amazing as to just how much stuff is going on in some of these pictures, once you start really looking at 'em closely.

Return to 16streets.comACRONYMS LOOK-UP PAGEMaybe try to email me? |